Challenge

DRANCO engineers and manufactures biogas plants that convert domestic waste to heat. In the next stage, this heat is converted to electricity.

We have been working with DRANCO for many years for the electrical automation at their clients’. Nationally as well as internationally.

Recently, it was up to us at the intermunicipal environmental companies Ecowerf and Verko. Ecowerf is active in East Brabant, Verko in the Dendermonde-Wetteren region.

The installations were delivered on site, after which we took over for the electrical automation.

Our approach

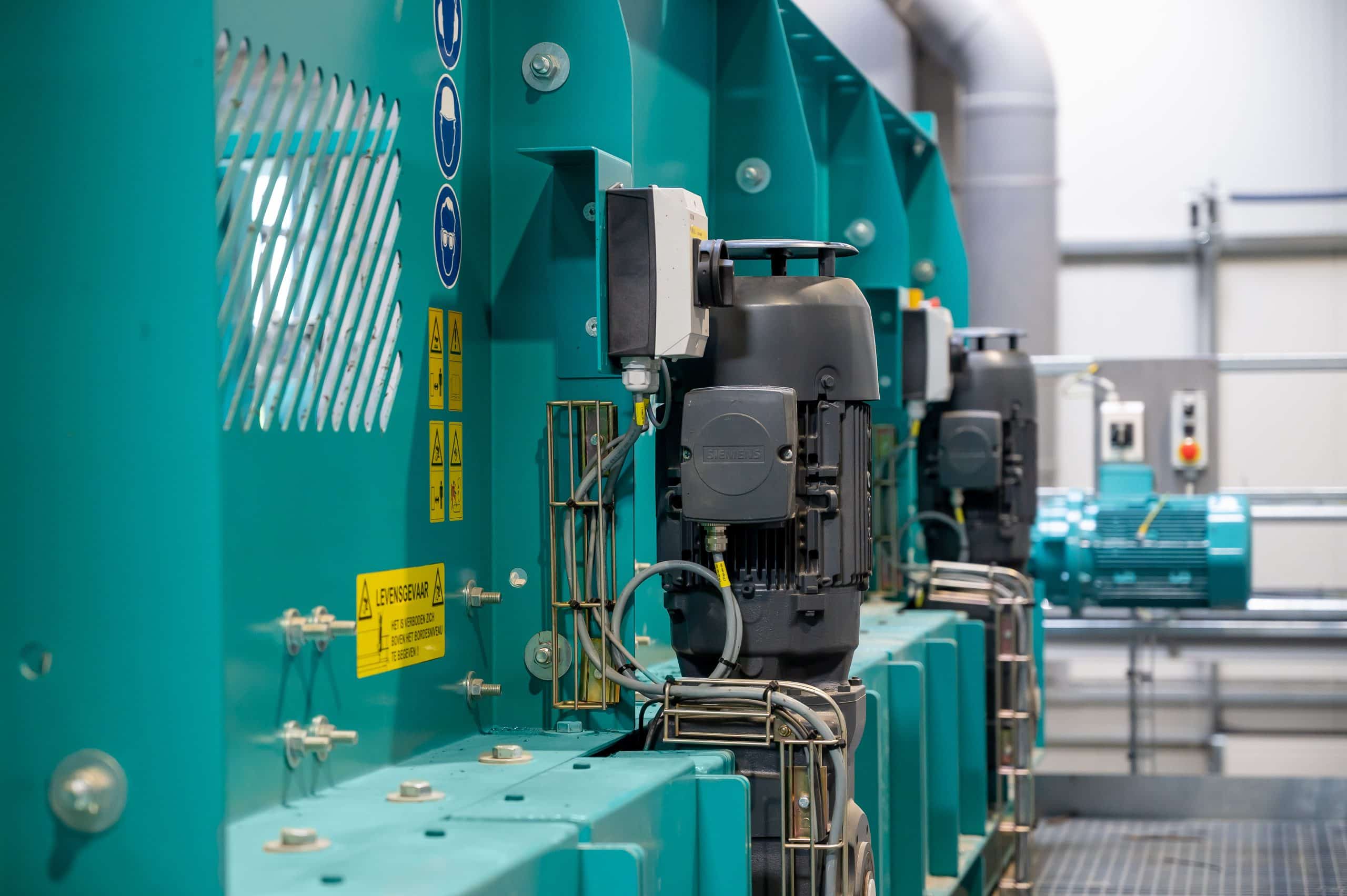

Based on the wiring diagrams of DRANCO, we assembled the electrical installation:

- Main electrical panels,

- Terminal boards,

- RIO-boards,

- Operating panels.

Furthermore, we translated the layout and piping and instrumentation diagrams (P&ID) into the correct field instruments and motors.

On site, we installed the boards and panels, including the cabling. DRANCO fitted the field instruments and motors themselves. We connected them and provided labelling and numbering.

Then, together with the DRANCO PLC programmer, we performed the I/O-checks, to lastly commission the installation, in collaboration with the client’s team.

Result

Every time a successful electrical automation of a new installation.

With us, Ecowerf and Verko got a dedicated team on site and a clear visualisation of the planning. And the assurance that the machine will work as intended, within budget and within the defined timeframe. This enabled their team to focus as much as possible on the daily processes.

For DRANCO, we took this fitment completely out of their hands so that they can focus optimally on their core business: the engineering and construction of biogas plants. Partnering with us ensured them that everything on site was taken care of. Even some lastminute concept changes.

The + summarised for these electrical automations

- Flawless production start-up.

- Correct operation of the installation.

- Electrical project management and site management.

- Detailed planning of the implementation of the works.

- Selection of suitable subcontractors.

- Coalition of these subcontractors.

- Communication/coordination with DRANCO and the end client.

- Fast and flexible solutions during planning and concept changes.